Knowledge that has been Around for a Very Long Time

Post and beam systems have been on this planet for thousands of years. In fact, Stonehenge dates back to 2,300 B.C. (roughly 4,310 years ago), according to scientists carbon dating related sites, per the National Science Foundation. While most people alive today may not think of an ancient stone structure as post and beam, it actually is a version: post and lintel. The posts are the vertical elements carrying the gravity loads into the ground. The lintels are the horizontal spanning “beams” that allow the space between the posts.

In Egyptian structures, a similar system was used, also with stone.

In the Temple at Karnak, for example, the posts or columns are made of multiple pieces of stone placed together to create large stone posts. The lintels or “beams” above only spanned a short distance, as the stone posts were located close together. The reason for this is that stone does a good job of handling compressive forces. That’s like when weight from above bears down on the ground. Unfortunately for rock, it is weak when it comes to tensile forces. This is what the underside of beams (or lintels) experience when spanning between posts. The greatest amount of tension exists in the middle of the beam, where it sags the most from the effort of resisting gravity and is farthest from the points of support from the posts. Early rock builders experienced this firsthand, when stone lintels came crashing down around them due to this tension force pulling the stone apart on the underside of stone beams.

Today’s Post and Beam Structures

In modern concrete post and beam structures, structural engineers have learned to use steel bars inside the concrete to resist the tensile forces. For instance, there is a major concentration of steel rebars inside the concrete beams nearest to the bottom of beams, where the tension forces are greatest. There is typically less steel rebar reinforcing along the top of concrete beams, as that is where the compression forces are, which concrete likes.

Wood Post and Beam Homes

What about wood? Wood is probably what most of us consider “post and beam” structures to be for homes and other structures. Wood happens to be a fairly decent material at handling compression and tension. This is why you see most homes across the United States being made of wood. Wood beams can span reasonable distances and in the form of engineered products like trusses and laminated beams and composite materials held together with glue and other attachment plates and the like, the spans can be 35′ up to 60′ in some housing construction projects.

But let’s focus on what we all think of today as post and beam. These are typically structures made of solid timbers. What are timbers? Logs that have been trimmed and cut, usually. What are logs? Trees that have been cut down from a forest.

So, timber structures are trees that have been trimmed, often into rectangular shapes. Why rectangular for many post and beam structures? Because there are horizontal flat surfaces on which the horizontal beams can comfortably bear on the tops of posts. Or on the notches made in posts. Why wood? Because as compared with stone and concrete, wood is relatively light and usually less expensive. How about steel? Steel is actually one of the most efficient structural materials on our planet. But it has higher embodied energy (it has to be melted at high temperatures in special steel factories like in Gary, Indiana, then transported around the planet, which also adds to its cost). Even so, steel is a good alternative and just about the only choice for super-tall structures like skyscrapers. But steel does not have the warmth and appeal and texture of wood, does it? Especially for a house. Also, you can’t just go out into your local forest and chop down a steel log, can you? Wood is much easier to find, at least in the USA.

Timber Frame vs. Post and Beam Homes

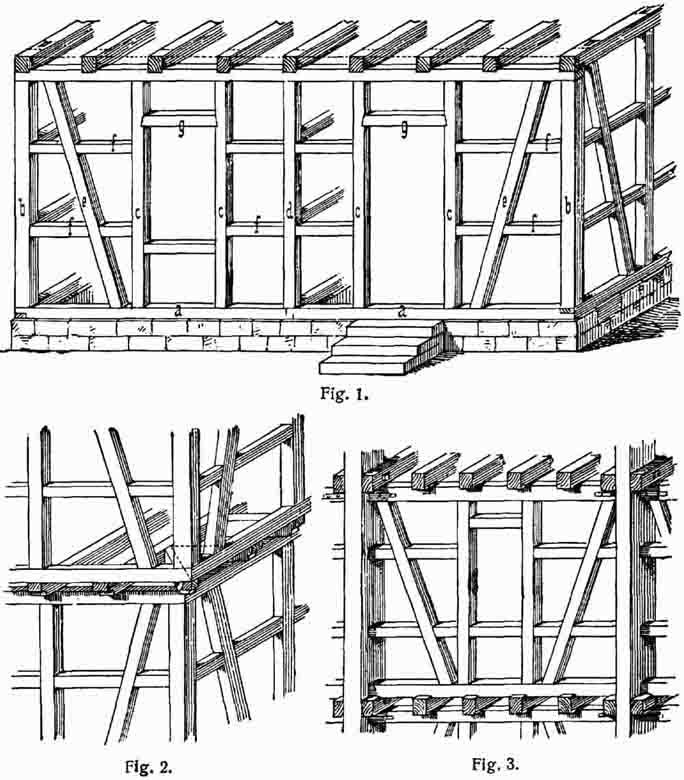

One may well ask, “What is the difference between timber frame and post and beam?” That is a very good question. Why? Because you cannot have a timber frame without the posts and beams. You can have a post and beam home without it being a formal timber frame, however. What does this mean? Well, timber frame structures are sort of a fancier version of post and beam systems. Any timber frame must first begin with vertical posts. Then there are horizontal or vertically diagonal beams.

Okay, now begins the fancy parts. You can take other vertical and diagonal and horizontal timbers, usually of smaller size and add these to the post and beam system to create a timber frame. What do these added elements do? Many of them are vertically diagonal struts that are secured to the joint several feet or inches from the intersection of the post and beam. This strut is a brace. In fact, this practice is called Bracing. It greatly strengthens the joint between the post and beam. If you are in an earthquake zone, for instance, these braces would be highly advisable, because they make the joint between the post and beam so much stronger.

Cavemen and Post and Beam Logs

Even so, there are many simpler post and beam structures in America and the world. Let’s face it, when evolving humans came out of trees and out of caves and starting creating basic shelter, you couldn’t get much simpler than cutting down what was around you: trees. Then you stood up some of these trees where you wanted your shelter to be located, then cut down some more trees and hoisted them over the tops of the vertical trees (posts). Mankind quickly learned that it was good to have some sort of durable connection between the horizontal trees (beams) and the post trees. Why? Because in a stiff wind, earthquake, or shoving from roaming creatures or hostile people, the beams could come falling down off of the posts, possibly maiming or killing you, along with dissolving your home.

Post and Beam Attachments

The methods of attachment in early structures were probably strips of leather made from the skins of animals harvested for food, or possibly vines and other plant material. In time, with the invention of boring and cutting and shaping tools, holes could be bored through the beams and into the post tops. These holes were probably at a diagonal. This is because end-grain is notoriously slack at holding nails or other items. Cross grain is much stronger. Then, shaped wooden dowels were hammered through the beams and into these post bore holes to secure the beams to the posts. Amish construction today still uses wooden dowels, as does most hardcore timber frame fabricators. These dowels are often made of oak and structural analysis indicates that they are about 75% as strong as steel bolts. In today’s post and beam homes, steel plates and through-bolts or lag bolts are often used, along with Timberloks (very long steel screws with high shear strength). You need an architect to detail these connections, because log screws typically have hex heads and these can be ugly if left exposed. A post and beam architect will know what to do.

Once you have your post and beam system, you need to provide and install infill walls and infill roof to weatherproof your structure. These infill systems and materials are as plentiful as the human mind is creative. Many post and beam homes use simple wooden stud wall infill. In fact, the best way to do this is to build the stud wall outboard of the post and beam, that way you do not have the time-consuming issues of stopping and starting your wall and this is also much more weatherproof than interrupting your wall at each post. Roofs can be standard roof trusses, or beams and dimension lumber joists with plywood, or SIPs (Structural Insulated Panels).

Contact Information:

Rand Soellner Architect

www.HomeArchitects.com

1.828.269.9046

Resources and Links:

National Science Foundation Article from ScienceBuzz: http://www.sciencebuzz.org/blog/archaeologists-pinpoint-stonehenge-construction-date-wally-

BBC article: http://news.bbc.co.uk/2/hi/science/nature/7625145.stm